Monday, September 24, 2012

Small Steps

Yay, small steps! I finally got around to ordering the replacement pressure plate bolts from Walck's a couple of weeks ago. Got a UPS tracking number and I noticed that the shipping weight listed it as 10 pounds!? Huh, for six bolts, lock washers and a keychain? Oh well, got the box last week and its huge and HEAVY! I open it up and yup, its a whole pressure plate! Got in contact with his wife this past weekend and she sent the bolts out which I got today and pre-paid packing slip to mail back the plate which I did today.

Spent a few minutes out in the barn with one of my sons and now have the clutch and pressure plate re-attached. Now, I just have to find what I did with four missing bellhousing bolts and I'll be back on my way with things!

Saturday, September 8, 2012

An "Easy Out"

Slow progress/ no progress... Forgot to post that last week I did get that broken bolt out. I bought an easy out set that seemed to have alot of recommendations as well as being an American made product, from Alden. They make a line of easy outs for both bolts and screws. They seem to roughly all work the same way. One end of the bit cuts a centering hole and then you switch it around and the other end acts as the reversed thread shank that cuts and grips the bolt to pull it out. You get the idea...

Anyways, bought a set and I started to cut into the bolt just to find out that the pressure of the cutting end was enough to back it out enough that I easily got a pair of pliers onto it and unthreaded it... :?

To have gotten a grade 8 bolt to snap off I thought that the bolt would have been too torqued in there to get it to unthread that easily otherwise I would have tried it. Oh well, live and learn. I still have to get a new set of bolts from Walck's before I get to start over again with the clutch!

Saturday, August 18, 2012

A Lesson Learned...

So I also need to invest in something better than my little old tap and die set. Anyone have a recommendation for a good quality, preferably American made set? Or should I be looking for a thread chasing set or re-threader set?

Yep, I learned a lesson today! Like I said, I thought to myself on the third turn, why is this bolt so loose? At the end of the fourth turn I knew that it hadn't been loose at all... But with that extra leverage provided by the long handle I hardly knew how hard I was torquing it. Wish that I had been using my old needle type wrench... lesson learned, I guess...

Yep, I learned a lesson today! Like I said, I thought to myself on the third turn, why is this bolt so loose? At the end of the fourth turn I knew that it hadn't been loose at all... But with that extra leverage provided by the long handle I hardly knew how hard I was torquing it. Wish that I had been using my old needle type wrench... lesson learned, I guess...

One Step Forward And Two Back

One step forward and two back today, man am I bummed... :(

But first the good news- I spun the pilot bushing on the end of a taped up bit on my drill and ran the bushing over some sandpaper and took a few thousandths and lo and behold it went in easily with a rubber mallet and a few more gentle taps from a sledge.

Torqued down the flywheel and cleaned and repainted the T90's metal mount and got the old transfer case mount out of the crossmember. I was on a roll! Decided to clean up the pressure plate and put in the clutch. I was just about to call it a day while I torqued the bolts... The third bolt seemed to either be loose or had alot of slack in it and just before the message got through my thick head that I should stop because the torque wrench wasn't clicking... snap... sheared a bolt off in the flywheel. :(

Got a bit too eager. I should have stopped and replaced the old bolts. Instead I was using the old pressure plate bolts. Probably didn't have anything to do with it though. With all the reach of the torque wrench it put too much on the bolt... Just don't know why it didn't click.

So.... now I have to replace my old drill as it's shot and try to drill out the bolt... it didn't even have the decency to snap off with any thread showing so I could have tried to get it out with a wrench...

Sunday, August 12, 2012

Another Sunday...

Didn't get much done today, still too damned humid to feel like moving. Tried tapping in the pilot bushing after taking it from the freezer... Hmmm... short of using a press (which I don't have...) anyone have any creative solutions for driving a new one in? I've tried using the input shaft as a guide but still manage to start pushing it in cockeyed. I mean they're pretty cheap but I'd rather not damage it too badly before I get it back in the flywheel. Comparing the old one to new slid onto the shaft you can feel some very slight... like 1/64" slop but its enough that I'm glad that I replaced it... well trying to replace it!

Still bashing away at the collar of the old transfer case mount now painted within the crossmember mount. I've got it started to separate with a chisel and punch, but that sucker is still firmly seated. So after losing a pound or so in sweat I decided to call it a night.

Monday, August 6, 2012

Wrestling With A Flywheel

Another scorcher today that really sapped my drive. Got a bit done though... Cleaned up the flywheel to look nice and purty with a bit more degreaser and then tried the unconventional 150 grit sandpaper and random orbital sander on it. Didn't go crazy with it, just got her nicely buffed and shiny. Took off the stubborn bits of grease.

Popped out the pilot bushing easily enough using the grease and input shaft trick...

I wasn't convinced that it was going to work, but wow, was I surprised! I'm freezing the new one and then I'll try tapping it in with the end of the input shaft again unless anyone has a better idea?

The aforementioned 'SP' initials on the front oil pan facing side of the bellhousing shield.

Pretty sure that it isn't a random set of scratches... who knows who 'SP' was!

Anyone know what this could have been or where it came from? It looks like a rounded lock washer with pointed ends... I found it somewhere near the rear of the engine after removing the clutch.

Closer view...

Lastly... I went to set the transfer case mount in today as well and discovered that it didn't fit. Looks like when I was cleaning up the old deteriorated one I left the old bottom metal seat of the old one in its cup in the crossmember. I remember scraping out the rubber from this cup when I was first cleaning up the frame, but that was all that came out. Just wanted to make sure before I start to chisel this piece out.

Saturday, July 28, 2012

The Summer Of 2012 So Far

A bunch of new entries all compressed into one for the months of June and July. Its all taken from forum entries so it asks questions and then answers them as I've figured them out. I ordered a bunch of parts from Walck's that I hope will enable me to get a rolling chassis back together by the fall!

How the Mistress is currently sitting, engine propped up on scrap lumber and on her engine mounts.

Back of the flywheel. What's involved with cleaning this up? Some light grit sandpaper for the rust spots left by the disc and degreaser? Other than the 'ghost' image left by the clutch disc, it seems in good shape, not obviously worn down or glazed, all teeth intact...

Flywheel side of the clutch disc, some wear, but I am not sure how much is too much. It DOES have a bit of grease and schmutz on it, so maybe I should just replace it?

Pressure plate side, again, not much wear.

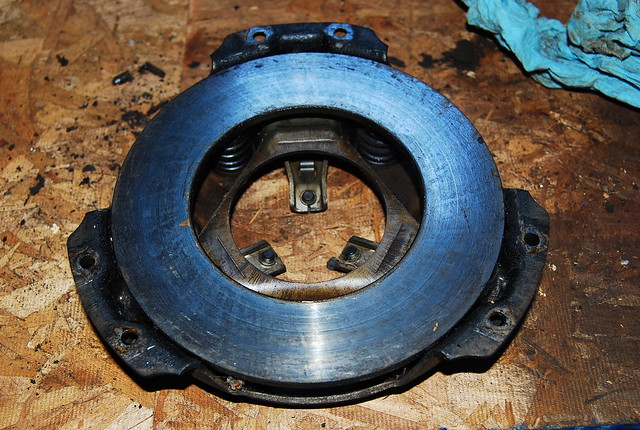

Pressure plate. Looks good to me. The three fingers all work smoothly and are hopefully adjusted fine.

Rear view.

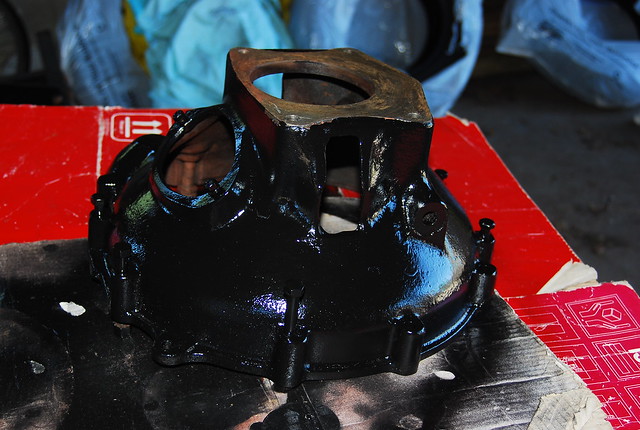

And the bellhousing that I spent some time degreasing and scraping a pound of dirt and grease from before painting.

I may as well replace the pilot bearing while I'm at right, right? And the throwout bearing seems to move pretty smoothly, but probably just another replaceable part?

So, been giving this alot of thought lately and here's roughly what I hope to accomplish this summer/fall.

First off, the Mistress is sitting on her rear axle with the engine on blocks in the rear and on the mounts in front.

I need to do the following:

1) Finish disassembling the T90, clean the accumulated 1-2" of solid dirt, mud and grease from the case, rebuild and paint it.

2)I also took the flywheel off today to try and figure out if there's an easier way of getting the front crankshaft pulley nut off without an impact wrench. I actually have a cheap-o HF one, but after a couple of uses it's broken... figures... Wish that I could afford a decent Milwaukee or something but not right now. How much can you reasonably expect to degrease a flywheel? I mean, mine isn't covered in grease where the clutch disk touches, but the exterior of that is sorta sticky to the touch like old, old dried grease has been flung up and sullied it up over the past 60 years. Other than that it isn't scored up nor does it look really bad, but should it be ground down at all? Also need to get the pilot bushing replaced using the old grease method, change the clutch and throw out bearing.

3) In general I need to scrape and degrease and eventually paint the entire engine. After that a general tune up is in order, rebuild the carb and get all the other misc. plumbing done for fuel and oil lines.

I'll need to take care of the broken studs on the exhaust manifold and I may even try it myself once I get a decent corded drill and a few new taps. My old Dewalt cordless needs its brushes replaced (I think... screeches like a banshee if you do anything other than drill a simple hole in soft wood...) I'm inspired by this writeup and I think that I can do it if I take my time with it. Otherwise I think that a startup of the engine can manage with the manifold as it is if I can get the old section of exhaust pipe out of the manifold's flange until I get to the repair and new studs. It seems pretty solidly attached to the block but who knows if there is or isn't a leak there.

Then I have to pull the head and hopefully get it all torqued down correctly. The two bolts in either corner aren't flush with the top of the head and I'm hoping that Bubba didn't try to replace two of the head bolts with two slightly longer bolts. The top of the head is also covered with some old foul oil in small pools. Bad rings or guides? Guess that I'll check compression when I can as well and possibly do a ring job with the engine installed.

4) As soon as I get the T90 back in place and the the transfer case degreased, rebuilt and painted (and with hopefully no new parts needed other than the basic gasket and oil seal set that I ordered) I need to pull the oil pan and check out the pick up, clean out the sludge and cross my fingers that the crank looks good and there isn't any other obvious damage internally. It all turns normally, the rockers all move as they should and I'm hopeful.

5) Then its a small job of getting the springs and front axle and shocks back together and the Mistress should be rolling on two tires that hold air and two that don't! And then after the fuel and oil lines, radiator (which hopefully holds water well!) and maybe even brakes (of which there was nothing to salvage but the backing plates... can't even rebuild the wheel cylinders... I hope that I 'll be able to rebuild the master though...) then I should have a rolling chassis that I can possibly drive around thew driveway!

And then after the fuel and oil lines, radiator (which hopefully holds water well!) and maybe even brakes (of which there was nothing to salvage but the backing plates... can't even rebuild the wheel cylinders... I hope that I 'll be able to rebuild the master though...) then I should have a rolling chassis that I can possibly drive around thew driveway!

6) Then its *only* a matter of patching up the body, the wiring, the brakes and lines, lights, new fuel tank, seat padding, new tires, gauge repairs and I'll have a street legal jeep! :D

First off, the Mistress is sitting on her rear axle with the engine on blocks in the rear and on the mounts in front.

I need to do the following:

1) Finish disassembling the T90, clean the accumulated 1-2" of solid dirt, mud and grease from the case, rebuild and paint it.

2)I also took the flywheel off today to try and figure out if there's an easier way of getting the front crankshaft pulley nut off without an impact wrench. I actually have a cheap-o HF one, but after a couple of uses it's broken... figures... Wish that I could afford a decent Milwaukee or something but not right now. How much can you reasonably expect to degrease a flywheel? I mean, mine isn't covered in grease where the clutch disk touches, but the exterior of that is sorta sticky to the touch like old, old dried grease has been flung up and sullied it up over the past 60 years. Other than that it isn't scored up nor does it look really bad, but should it be ground down at all? Also need to get the pilot bushing replaced using the old grease method, change the clutch and throw out bearing.

3) In general I need to scrape and degrease and eventually paint the entire engine. After that a general tune up is in order, rebuild the carb and get all the other misc. plumbing done for fuel and oil lines.

I'll need to take care of the broken studs on the exhaust manifold and I may even try it myself once I get a decent corded drill and a few new taps. My old Dewalt cordless needs its brushes replaced (I think... screeches like a banshee if you do anything other than drill a simple hole in soft wood...) I'm inspired by this writeup and I think that I can do it if I take my time with it. Otherwise I think that a startup of the engine can manage with the manifold as it is if I can get the old section of exhaust pipe out of the manifold's flange until I get to the repair and new studs. It seems pretty solidly attached to the block but who knows if there is or isn't a leak there.

Then I have to pull the head and hopefully get it all torqued down correctly. The two bolts in either corner aren't flush with the top of the head and I'm hoping that Bubba didn't try to replace two of the head bolts with two slightly longer bolts. The top of the head is also covered with some old foul oil in small pools. Bad rings or guides? Guess that I'll check compression when I can as well and possibly do a ring job with the engine installed.

4) As soon as I get the T90 back in place and the the transfer case degreased, rebuilt and painted (and with hopefully no new parts needed other than the basic gasket and oil seal set that I ordered) I need to pull the oil pan and check out the pick up, clean out the sludge and cross my fingers that the crank looks good and there isn't any other obvious damage internally. It all turns normally, the rockers all move as they should and I'm hopeful.

5) Then its a small job of getting the springs and front axle and shocks back together and the Mistress should be rolling on two tires that hold air and two that don't!

And then after the fuel and oil lines, radiator (which hopefully holds water well!) and maybe even brakes (of which there was nothing to salvage but the backing plates... can't even rebuild the wheel cylinders... I hope that I 'll be able to rebuild the master though...) then I should have a rolling chassis that I can possibly drive around thew driveway!

And then after the fuel and oil lines, radiator (which hopefully holds water well!) and maybe even brakes (of which there was nothing to salvage but the backing plates... can't even rebuild the wheel cylinders... I hope that I 'll be able to rebuild the master though...) then I should have a rolling chassis that I can possibly drive around thew driveway!6) Then its *only* a matter of patching up the body, the wiring, the brakes and lines, lights, new fuel tank, seat padding, new tires, gauge repairs and I'll have a street legal jeep! :D

Ok, I finally had the time to start with tearing into the T90 today and it came apart (mainly...) as slick and simple as butter... that is once I took a better look at things and took my time. That problem that I was having with the main shaft was due to not having taken out the two bolts for the oil collector. Once that was done the countershaft came out easily, dropped the cluster gear and with a little finagaling with the oil collector the main shaft came right out! Between Doug's write-up and this one- http://www.cj-3a.com/T-90%20Rebuild.htm by Rick Stivers its all started to make some sense. I ran into a bit of trouble with having to remove some washers from the end of the cluster gear in order to be able to move it around a bit more so that I could get the oil collector out and then the mainshaft. Now for the big problem, the reverse idler gear shaft... I'm using a 3/4" wooden dowel instead of a brass punch but I cannot for the life of me figure out how to drive it out. You cannot get at it in a straight line and I've tried the C-clamp idea that Stivers suggests too, but so far, nothing... Wish me luck with a bit of sleep tonight that I may have more luck with it.

A friend of mine on my forum suggested a 1/2" socket extension and I'll be damned if it didn't work perfectly. I tapped it a few times and moved it about 1/8". I was hesitant about moving it out the rest of the way with the extension as I didn't want to cock it and jam it by hammering on it at an angle. It came out the rest of the way with the dowel as easily as the countershaft. Just a matter of getting it started as the original idea man had said!

I started getting alot of work done on the T90 today and one of the gems that I uncovered was the original casting date for the case... July 29, 1953! How about that!?! A week from today it was cast 59 years ago! Pretty cool! I love dates on things like this and was hoping to find some frame numbers when I cleaned up the frame, but this almost makes up for it. I didn't know that these existed until I chanced across a reference to it on the 2A Page here. As the OP said, the fake screwheads are a nice touch!

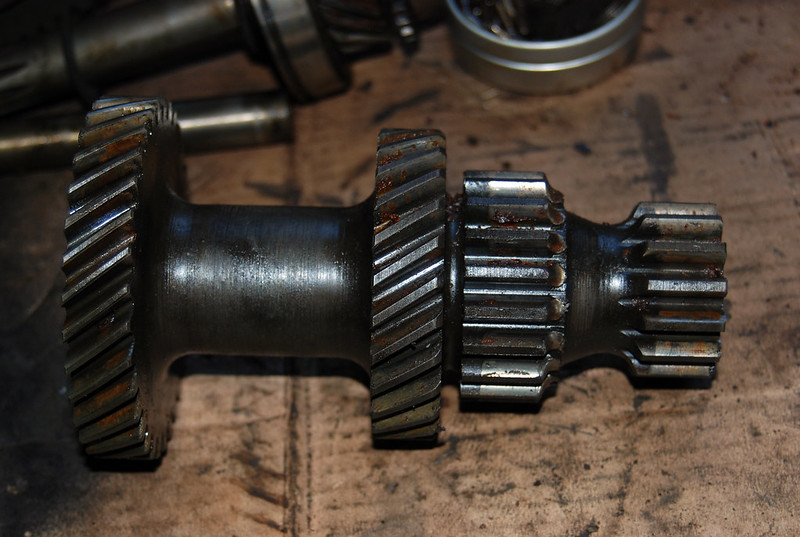

The mainshaft gears. Mainly a bit of surface rust but you can see some wear on the large gear's right hand teeth on the sliding gear or the 1st/Reverse Sliding Gear as Stivers refers to it here- http://www.cj-3a.com/T-90%20Rebuild.htm. I think that it's related to the excessive wear on the countershaft/ cluster gear set.

And speaking of which...

Anyone have any experience with how much wear is too much. Stivers says 3/8"... Guess that its time to break out the file and dress 'em up a bit.

Got nice and dirty with the grinder and wire wheel. Its messy but does a nice and quick job of thick accumulated grease and dirt. A bit of Simple Green and a couple of shop rags later and its looking almost ready for paint! Still gotta get into the corners and niches with an old toothbrush and then it'll be Rustoleum time!

And another little mystery. Anyone have an idea about the stamped numbers on the lip of the top plate? "56", "61" and "H183-3"

Subscribe to:

Posts (Atom)